Truck Facts

The International Harvester R-Series Rear Axle

(Source: International Light Duty Trucks, International Harvester Co., Publication CR-485-C)

Proved long-life rear axle

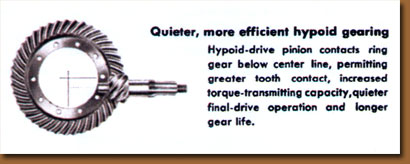

Hypoid gearing, heavier housing, wider wheel bearing centers, improved axle ratios, and straddle-mounted pinions are some of the reasons why new International Truck rear axles offer more miles of trouble-free performance.

These improvements, made possible by engineering and manufacturing refinements, provide greater load-carrying capacity per pound of axle weight and proper axle ratios for operations under most severe conditions. They provide greater safety, greater dependability, greater assurance of longer life.

- Wide-base rims increase road stability, prolong tire life, make tire servicing easier.

- Powerful 4-wbeel hydraulic brakes. Self-centering, self-energizing, two-shoe type designed for maximum braking efficiency. Special brake design permits quick, easy adjustment.

- Large-capacity, tapered-roller bearings, wide-spaced for better stability and load support.

- Large-size brake drum easily removed, easily replaced without disturbing other brake parts. Pressed steel back fused to cast-iron braking surface to add strength, cut down weight.

- Self-cleaning slinger and labyrinth-type brake drum seal keep out dirt, mud and moisture; lengthen life of brake lining and drums. Rib reinforces drum, throws off heat.

- Heavy-duty, pressed-steel disc-type wheel.

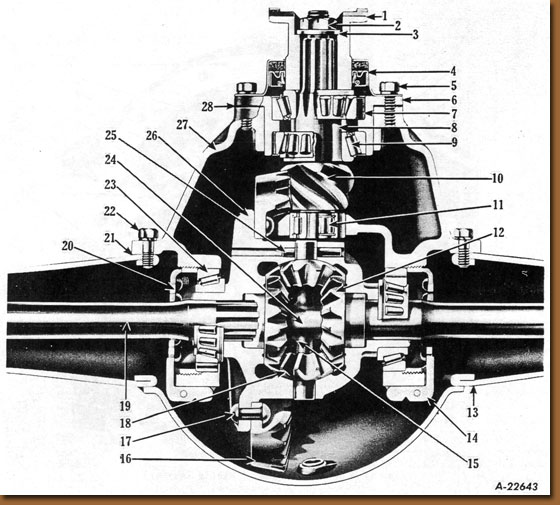

- One-piece, tubular, banjo-type housing.

Large-diameter, 16-spline, heat-treated, chrome-nickel-molybdenum, shot-peened steel axle shafts with integral flange. (R-120 and R-130 Series models have full-floating axles; R-110 Series models, semi-floating.)

Large-diameter, 16-spline, heat-treated, chrome-nickel-molybdenum, shot-peened steel axle shafts with integral flange. (R-120 and R-130 Series models have full-floating axles; R-110 Series models, semi-floating.)- Long-lasting differential gears distribute balanced power to axle shaft. Replaceable, hardened thrust washers eliminate differential case wear.

- Accurately matched hypoid ring gear and pinion.

- Efficient oil seal and dust shield.

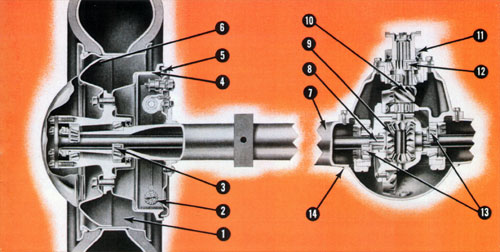

- Straddle-mounted pinion, three heavy-duty roller bearings for firm alignment with ring gear.

- Large-capacity roller bearings for long life.

- Heavy housing cover welded on. Welding eliminates gasket leaks, provides rigid differential bearing support, and increases sturdiness of housing.

Single Reduction Hypoid Axle (R-1060)

| 1. Companion flange. | 15. Differential cross pin. |

| 2. Propeller flange mounting nut. | 16. Hypoid ring gear. |

| 3. Propeller flange mounting nut washer. | 17. Hypoid ring gear rivet. |

| 4. Pinion shaft bearing oil seal. | 18. Differential pinion. |

| 5. Pinion bearing cage to carrier capscrew. | 19. Axle shaft. |

| 6. Pinion bearing cage. | 20. Differential bearing adjuster. |

| 7. Pinion bearing, outer | 21. Differential carrier to housing gasket. |

| 8. Pinion bearing spacer. | 22. Differential carrier to housing capscrew. |

| 9. Pinion bearing, inner. | 23. Differential roller bearing. |

| 10. Hypoid pinion gear (straddle mounting). | 24. Differential center block. |

| 11. Pinion bearing. | 25. Differential cross pin retaining pin. |

| 12. Differential side gear. | 26. Differential case. |

| 13. Axle housing. | 27. Differential carrier housing. |

| 14. Differential bearing adjuster lock. | 28. Pinion bearing cage shim. |